century-win

Focus on the R & D and production of injection molding machinery

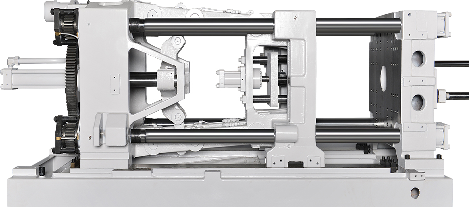

Model:

230GK/290GK/360GK

Function introduction:

Finite element analysis and design, high-strength formwork, frame and machine hinge are thickened to effectively prevent deformation and fracture; The fully closed mold locking door can effectively prevent foreign matters from entering the mold locking device, which is more beautiful and safer. The mechanical safety door adopts the brake line brake device, which has reliable performance, flexibility and convenience.

The high-strength formwork and machine hinge structure design has better rigidity than the formwork of conventional injection molding machine.

Larger internal spacing of pull rods can install molds with larger appearance.

The wear-resistant sliding foot inclined iron base plate of the mobile formwork is enhanced, so that the weight of the mobile formwork is stronger. The new built-in adjustment free safety mechanical rod reduces exposure and has higher safety.

The reliable precision of mold opening and termination is perfectly matched with automatic production auxiliary equipment, such as automatic manipulator, visual system, mold safety monitoring system, etc.

The design of double jet moving oil cylinder ensures that the force on the center of the jet nozzle is uniform and is not easy to leak glue.

European trend, single cylinder integral injection design, fast injection speed and rapid response.

Linear guide rail support, small moving resistance of shooting platform and high precision.

The single injection cylinder reduces the weight of the parts of the injection table, reduces the motion inertia in the glue injection process, effectively improves the accuracy of the end position of the screw during glue injection, and greatly improves the weight accuracy of the molded products.

Original Japanese closed-loop electronic variable displacement pump (EH).

Multi loop design can realize mold opening and closing, glue melting, ejection (neutron) synchronous action (EHT).

Increase the hydraulic system for faster speed (EHF).

Electro hydraulic mixing (ehth), the perfect combination of hydraulic injection molding machine and all electric injection molding machine, the advantages of the two models complement each other.

The original Japanese variable displacement pump plus servo motor drive (SV) is more energy-saving on the premise of ensuring high speed and high precision.

Smartmold controller is a standard injection molding machine controller specially developed by baccalais for the Chinese market. Smartmold integrates almost all functions in the control of injection molding machine, which can meet the configuration requirements of injection molding machine with any performance. Manufacturers can change the machine configuration as needed, which has strong flexibility.

Graphical and programmable process flow, convenient and fast modification

Most functions of the integrated injection molding machine are ready to use

Built in debugging wizard and online help, no additional programming tools are required for on-site debugging, and the debugging time is shortened by 80%

Hardware implementation of pressure maintaining switching control

IO visual free configuration

USB supports machine recipe interoperability

Support flexible manipulator interface (euromap67, euromap12, custom standard)