century-win

Focus on the R & D and production of injection molding machinery

Model:

DV-30/DV-45/DV-55/DV-85/DV-100/DV-120/DV-160/DV-200/DV-250

Function introduction:

Energy saving, high precision, high efficiency, environmental protection, reliability, fast firing speed, good performance, convenience and safety

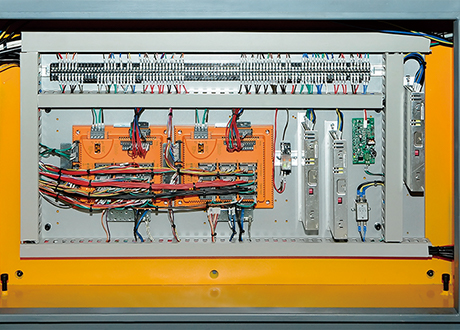

It adopts dual CPU control, the man-machine unit uses x86-300mhz industrial motherboard, and the system unit uses risc-140mhz reduced instruction set microprocessor, which has the characteristics of high speed, anti-interference, fan free and low power consumption. Independent control improves the stability of control.

The man-machine operating system distinguishes Linux, the operating system has high stability, and the startup speed is twice as fast as ordinary. All kinds of high expansibility, wide support of USB peripheral devices and high compatibility.

It also has other common functions, such as multilingual system, ejection end point display curve, firing speed pressure retaining ring display curve, temperature tracking display curve, dynamic recording parameter modification, dynamic alarm display, temperature PID control, multi pump control and molding parameter access.

Identify the modular design of PC base framework, which can be matched with modules (CPU & amp; PLC module, power module, 10 module, temperature control module and ADA module) as needed.

It adopts the original Austrian smartmold baccalais computer, CPU and DSP high-speed module, and the output module, backplane module, bus module, etc. with high control precision and fast response speed.

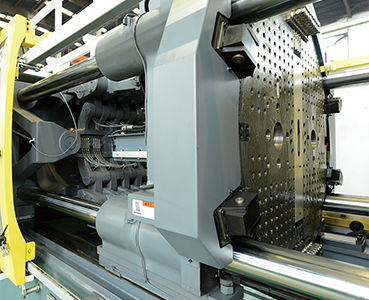

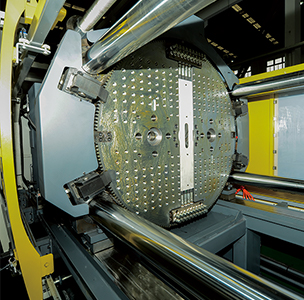

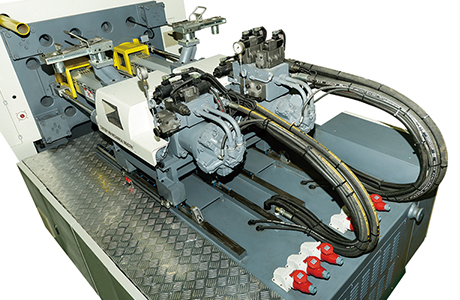

The switch mold, supporting mold and injection adopt potentiometers imported from Italy, with accurate and stable control. With mold cooling device, it is easy to use and does not drag and break the water pipe. Turntable positioning speed control, stable movement and high precision.

The unique turntable designed by Jiwei has no contact with the die wall to reduce the faults caused by friction, and accurate positioning confirmation is made before closing the die to protect the safety of the die.

The double injection cylinder structure is adopted to ensure the centering performance of the injection nozzle, reliable sealing, no glue leakage, and single cylinder integral injection. The bilinear guide rail injection structure has high precision, low friction coefficient, small and uniform resistance in the process of injection and plasticization, sensitive adjustment, single cylinder injection structure, greatly reduce the motion inertia during injection, and improve the injection speed and plasticization ability. Modular structure design provides a variety of choices.